News Archive 2009

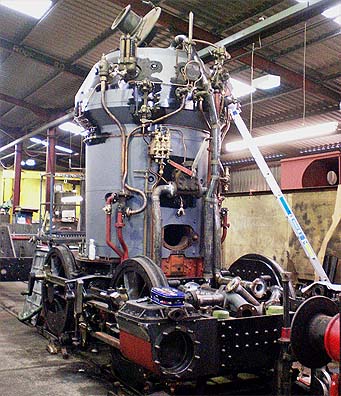

December 2009 - Power Bogie & Coach Interior

The main steam & exhaust pipes have now been manufactured, fitted and proved correct. The second expansion link has been fitted, and the connecting rod main bearings machined. Cylinder cocks have been delivered & fitted along with the operating linkage.

Machining of the remaining items of valve gear is progressing to programme and will be progressively fitted to the bogie as they become available.

The body and frames have been set level to allow construction of the boiler compartment to continue - the front end is complete and clad, and work on the sides will continue as soon as the interior roof lining is completed in the passenger areas.

The curved exterior roof mouldings have been ordered for both ends and this will allow the roof canvas to be fitted. All interior partitions have been completed but doors not yet hung. Seven of the eight external doors & droplights have been delivered along with all interior mouldings and window vent mouldings. Bases for roof vents & gas lights have also been manufactured & delivered.

Fittings etc are being polished, powder coated or painted as appropriate ready for installation when required. All the framed pictures for both vehicles have been completed along with letter racks for the centre vestibules.

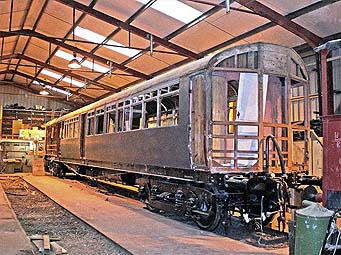

October 2009 - Cladding

During the couple of weeks covering the end of September and the beginning of October work on the coach side framework from the trailing end to the luggage compartment doors was completed.

This has enabled both the exterior marine ply and interior T&G cladding to be fixed in place along both sides, transforming the vehicle appearance from a skeleton to something approaching a railway coach, as the photos show.

A decision made some time ago to replace one of the main upright posts in the boiler end has now been implemented. The original timber was considered ‘a bit iffy’ and proved to be so when tested. New timber was ordered,and has now been profiled and jointed into place, so removing a possible source of trouble. The sanding of roof boards has also been completed and the canvas and adhesive delivered pending application.

Oct-09

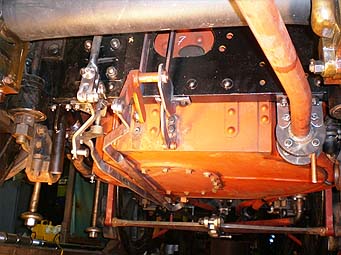

Power bogie and boiler work is also progressing, with all the boiler pipework and fittings now in place, except for the main steam and exhaust pipes which are currently being manufactured. Damper, sand gear and regulator linkages have also been installed along with the lubrication system, steam heat, injectors, main vacuum pipe and brake gear. Many of the motion forgings delivered over the past couple of months are currently being machined ready for fitting, with the expansion links already completed

September 2009 - Crew training

Sep-09

Four members from Didcot’s footplate crews have spent a number of days in Switzerland learning to operate a vertical boiler railcar under sustained steaming conditions, in preparation for the day when No 93 is steamed. Although some vertical boilers are in use in UK running for long periods under high steaming rates is not possible, and instruction in both vehicle operation and maintenance by experienced crews was considered essential before No 93 is used in anger.

Dampftriebwagen UeBB CZm ½ No 31, a 1902 built wooden body railcar operated by volunteers in Zurich was made available, and expert instruction was provided to enable experience to be gained in both the operation and maintenance. Didcot’s John Minchin, Mark Baldry, Peter Jennings and Graham Drew received instruction from crews based at Verein Dampfgruppe Zurich.

A trip was organised between Zurich and Glarus where No 31 took part in a Steam Festival before running to the line terminus at Linthal. – a long day with an 05.30 start and not returning to Zurich until almost midnight. An unforgettable moment was when we drove No 31 into the Linthal pub car park at the end of the day’s operations for a bite to eat and appropriate refreshments. – Try doing that in the UK!

A second day was spent doing a photo charter on the branch between Bauma and Hinwil, where No 31 originally operated, in conjunction with an assortment of departmental vehicles and coaches together with locomotive 401 which is based at Bauma. This branch has a steeply curved rising gradient within ¼ mile of the station start - a bit like the Looe Branch, but in reverse, and this tested the Railcar to the limit. A day spent doing photo stops, run pass and static sessions for the photographers was completed by assisting in the cleaning of No 401 to enable the crew to travel back to Zurich with us in the railcar – a main line ‘dash’ at 45KPH alongside international expresses and commuter traffic ending at Zurich’s main terminus. – again try doing that in the UK.

The third day was also spent on the main line with a return trip from Zurich to Baden where other main line steam stock is based, and more valuable operating experience was gained which can be passed on to the Didcot crews in due course.

Our thanks go to Fredy Landenberger and No 31’s crew who ‘did us proud’, and to the HLF who part funded the operation.

What they said - How the news was reported

Steam Railway - 16 October 2009

Heritage Railway - 29 October 2009

The Railway Magazine - 4 November 2009

August - Joints, Hoops & Cant Rails

Over the past couple of months work has steadily progressed on the repair of the hundreds of joints in the vehicle body framework, and at last we can see some progress. Each joint has been assessed for security and damage, and where necessary taken apart and either re-made or strengthened.

Where items have been secured with screws most have been found to have been badly rusted, as the GWR used plain steel screws. Each one has been removed, the hole plugged, and replaced with a new plated product, or if this is not possible a new screw has been placed alongside the old.

Aug-09

Particular attention has been paid to the joints between the roof hoops and the cant rails, and these have been reinforced with steel brackets as most were considered suspect and in need of some TLC. This is considered the preferred method of restoration, the alternative being the complete replacement of both hoops and cant rails. All the screws securing the roof boards to the hoops have also been replaced, and the boards are currently being sanded to obtain a smooth surface prior to fixing the canvas.

In addition detailed renovation of the main timbers where damage to the machined rebates has occurred is being progressed. This involves cutting away the quarter inch or so of damaged wood in an otherwise sound item and inserting new - again a tedious task that seems to take forever, with little to show at the end.

We have resisted the temptation to show a photo of every joint and rebate repair - just one of each to whet your appetite!

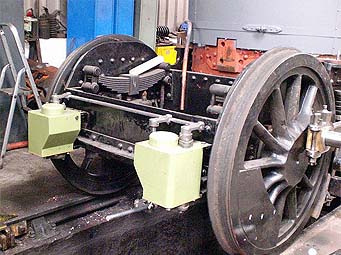

June - Rods, Sand and Hoops

At Llangollen, we have taken delivery of the completed connecting rods, piston rods, pistons and crossheads for the power bogie.

An order has also been placed for the manufacture and fitting of the big end bearings, together with assembly of all these parts. In addition the sand boxes and operating linkages have been fitted over the last couple of weeks.

Graham Drew - Jun-09

Now that the cladding is complete and the scaffold removed, work is progressing on the boiler pipework, regulator linkage and brake systems.

Arrangements are being made to send a set of our wheel rollers that we use at Didcot when setting up valve events up to Llangollen to assist in the setting up of the valve gear.

Work has commenced on renovation of the coach doors that can be salvaged, together with the manufacture of new where they are beyond repair.

Large quantities of various sizes of T&G boarding has been arriving on site for all the internal partitions and interior cladding as well as the floor top surface. Additional areas of wet rot that were discovered in the roof when the centre vestibule partition cladding was removed for renovation has fortunately not progressed in to the coach structure to a significant extent, and will not cause us any problems.

Steel stiffening hoops and angle brackets have now been fitted to the roof adjacent to the boiler opening to prevent excessive flexing in service.

What they said - How the news was reported

Steam Railway - 21 August 2009

May - Coachwork Continues

Work continues on the coach body, with many areas being addressed. The first part of floor (which consists of two layers) has been fixed, and the T&G top layer has been delivered ready for fitting, so we now have something solid to stand on

This has allowed work to start on the internal partitions, and these have now had the cladding stripped to allow structural timbers to be inspected. Water leaks over the years around the area of the centre vestibule has taken its toll on both the cladding and some of the supporting framework, and work is required on these before the cladding, most of which can be reused, is replaced.

Work has also commenced on the roof, with the boiler access and compartment vent holes being cut and roof hoops repositioned to allow clearance through the holes. The boiler access hole is 6' 6" square, and it has been considered prudent to reinforce the adjacent wooden roof hoops and cant rails with steel angle bracing to maintain structural integrity, so it has not just been a case of a quick chop-out with a jig saw. The roof boards have also been sanded in preparation for fixing the roof canvas. Boards removed when we cut the holes will be used to replace rotten sections over the centre vestibule.

GWS - May-09

Orders have now been placed for all the various sizes of T&G internal cladding required, along with either repairing or making new the driver's vestibule, centre vestibule and luggage compartment doors. The new external and internal sliding doors for the boiler compartment have also been ordered, together with internal partition doors that are considered to be beyond repair.

Work on the power unit has also progressed, with the boiler cladding and fire hole doors complete. Once the boiler fittings are re-installed the scaffold can be removed to allow work to continue on the pipes and other bogie systems. To this end the sandboxes and linkages have now been delivered, and manufacture is progressing on the lubricator and cylinder drain cocks.

April - Lots to see at Llangollen

With the wooden body now firmly bolted down to the underframe work has continued on renovation of the coach ends. The trailing end repairs have proved to be more extensive than the boiler end, with a higher proportion of the timber frames requiring replacement below window frame level due to extensive rot caused by loose fitting steel cladding when in service. The trailing end driver's vestibule floor has also required complete replacement, as this forms the base for the handbrake at this end of the vehicle and also access to the sand boxes. This was also suffering from excessive rot for the same reason.

Following return of the power bogie and boiler to the works after proving trials, work has commenced on the boiler and cylinder cladding together with the mechanical brake rigging. However brake work has had to be suspended for a short time as access proved to be impossible with the assembly clad in scaffolding to give the sheet metal workers a safe working platform. At the end of April, the cylinder cladding had been completed, and the boiler was about 60% done.

Visitors to Llangollen's steam gala were able to see the assembly in this semi-clad state, not too good for photography, but an example of work in progress that illustrates how things are done. The underframe and body were also on display at Pentrefelyn for those who didn't mind the ten minute walk down the road, as it was not possible to run the auto shuttle this year - there were too many locomotives on shed to make this feasible! We estimate over 500 took the trouble to come and see us in the works over the two weekends, based on the number of leaflets we handed out. Mid-week numbers are unknown as the display was not manned during that time, but another 100+ leaflets disappeared during the week.

The project has produced a 25 minute DVD of GWR Railmotor and Autotrailer history and development that was shown at Llangollen over the second weekend. This forms the first part of a two part presentation, the second part will cover the restoration of our two vehicles when they are complete. As a result of considerable interest being shown in this DVD - “can we buy a copy please?” - we are looking to produce some for sale in the shop at Didcot and by mail order. We will also see if an abridged version can be put on this web site, so watch this space for further announcements.

What they said - How the news was reported

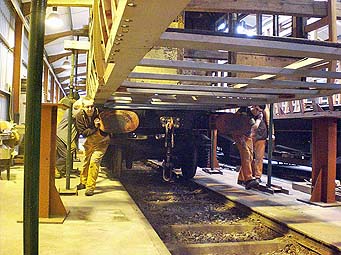

5th March - Friends Re-united!

The second major step in the Project this year was achieved on 5th March, when the underframe and wooden body were reunited in Llangollen's carriage shed workshops.

GWS - 05-Mar-09

The completed underframe was propelled from the loco. works to Pentrefelyn early in the day, and following a shunt of various DMU's to gain access to the shed, the stands that had supported the body since it was separated from the frames in December 2007 were removed, and the underframe was rolled into position.

The following day the body was lowered the two inches or so required to put the weight on the frames, and the queen posts adjusted to compensate for the weight to maintain the correct vertical alignment.

Apart from (we assume) being separated at Swindon for about seven months between November 1934 and May 1935 for conversion to a trailer, and the time at Llangollen, the two have been together for 101 years. It's hoped that the next body lift will not be for another hundred - keep viewing the web site for updates !

What they said - How the news was reported

Steam Railway - 3rd April 2009

February - ‘Australian Tram’ Seats Refurbished

The ‘walkover’ seats obtained from Australia for use on the project have now been restored and recovered in the correct pattern fabric. The work involved a complete strip of all component parts, repairs to the mechanisms where necessary, and modification to the backs to remove the chrome hand grab that was a feature not included in the seats fitted by the Great Western. In addition the ‘joggle’ in the back frame to reduce the width down the outer edge has also been removed to restore the full seat width.

The frames were cleaned by grit blasting before being powder coated in dark brown by a specialist contractor. Reassembly and recovering was done at Llangollen.

Apart from the compulsory dead spiders and large quantities of chewing gum stuck within the mechanisms, an interesting find within one of the cushions has been an Adelaide tram ticket, now regretfully out of date. As a result of the modifications carried out on the frames we now have 40 chrome grab handles looking for a good home - will suit anyone restoring bus seats - any takers?

February - Another Amazing Coincidence!

A coincidence, perhaps, to equal the saga of Australian seats!

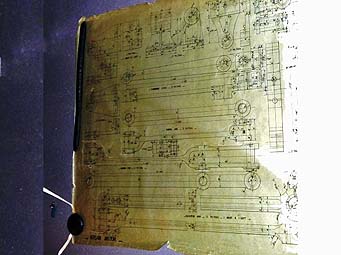

During work being done at the NRM in York at the end of 2008 by members of the County Project looking for drawings for their project, a small quantity of drawings were discovered relating to the Railmotor. Among them were two extremely fragile tracings of valve motion components - the very drawings that the Society has been looking for over the past five years or so.

The Project's well documented efforts that have gone into producing a set of working engineering drawings for the valve gear, resulting in the wood mock-up exhibited on the power bogie at Didcot, is well known. The acquisition of original drawings within days of the Project committing to cutting steel has confirmed that the design work is indeed correct, and we can now proceed with manufacture of components with renewed confidence.

Our thanks go to both the County Project who highlighted the find, and to Tim Procter at the NRM, who pulled out all the stops to personally photograph the drawings for us, as they are far too delicate to be scanned by a commercial machine. From these photos we have been able to produce reasonable A1 size prints to use as working drawings. - the wonders of digital manipulation.

27th January - Power Bogie and Boiler Trial Fitted in Underframe

The newly-built power bogie and boiler unit was trial-fitted to the vehicle’s refurbished 1908 underframe for the first time on Tuesday 27 January.

Adrian Knowles- 27-Jan-2009

The operation took place in the loco shed yard at Llangollen where the railmotor’s 70ft underframe was carefully lifted from its accommodation bogie and lowered onto the power bogie. Because the boiler of the engine unit is located where the bogie pivot would normally be, the power bogie uses the Dean ‘centreless’ system in which the weight of the carriage is carried on scroll arms at the side of the underframe, which in turn rest on two underslung transverse beams suspended from the bogie on springs.

Adrian Knowles - 27-Jan-2009

Dennis Howells, Engineering Manager for the railmotor power bogie, and vehicle Project Manager Graham Drew watched as Dave Owen and the Llangollen team located the scroll irons into the transverse beams and bolted up the suspension springs, before lowering the 5-ton boiler into position on top of the bogie.

Although we have taken a lot of care to get things right, we expected that there may be one or two issues, but all that’s needed is some adjustment of the suspension brackets on the bogie and a little easing of the buffing pads where the thrust from the power bogie is transmitted to the underframe.

Adrian Knowles - 27-Jan-2009

Once the power bogie was securely installed the entire rolling chassis was towed slowly out of the Llangollen shed yard towards Engine Shed Junction to prove its ability to negotiate curves and junctions. Nobody has built a Dean centreless bogie for more than a century, so we needed to be sure that everything had been made and assembled in the way that Dean originally intended.

Having completed its trial run without any problems, the chassis was taken back to the loco shed. The engine unit will remain in the chassis for about two weeks to make it easier to design the various pipe runs and other connections, after which it will be removed so that the underframe can be taken to the carriage restoration workshop at Pentrefelyn.

Work on the railmotor’s timber body has been progressing rapidly and has now reached the stage where little more can be done until the body is mounted back on the underframe. It is planned to do this by mid-February so that work can then proceed on the upper part of the body frame and roof.

Throughout the Steel, Steam and Stars 9-day mega-gala from 18 to 26 April, the power bogie and boiler will be on display to the public at the Llangollen Railway Loco Works, while the body mounted on the underframe will be on show at Pentrefelyn. Members of the GWS Project Team will be on hand at the weekends to demonstrate and explain various aspects of the project.

What they said - How the news was reported

Heritage Railway - 19th February 2009

The Railway Magazine - April 2009

Steam Railway - 6th March 2009

16th January - Power Bogie and Boiler Move to Llangollen

Graham Drew - 15-Jan-2009

With the Christmas holidays now but a memory the Railmotor team has returned to the project with some vigour.

Although preparations for the boiler and bogie move from Didcot to Llangollen were started by Dennis Howell and his team before the holiday, by the removal of most of the boiler fittings that had been temporary installed for display purposes, work started with a vengeance on the 13th of January with a shunt of all locomotives on one and two roads to release the assembly from the rear of the locomotive shed, and to allow access to the Lifting Shop for loading onto rail wagons by the 50 Ton hoist.

The boiler was loaded into the Society’s Concrete Sleeper wagon, but the power bogie, being too wide, had to be placed on a “Salmon” hired from D.B. Shenker (the new name for EWS).

Having been loaded, the consignment was inspected for security by the D.B. Loads Inspector, before the short trip to Didcot’s West Yard , where transfer by crane to road transport for the journey to North Wales was done. The trip to Llangollen was without incident, with unloading being done on Friday 16th January in the station goods yard.